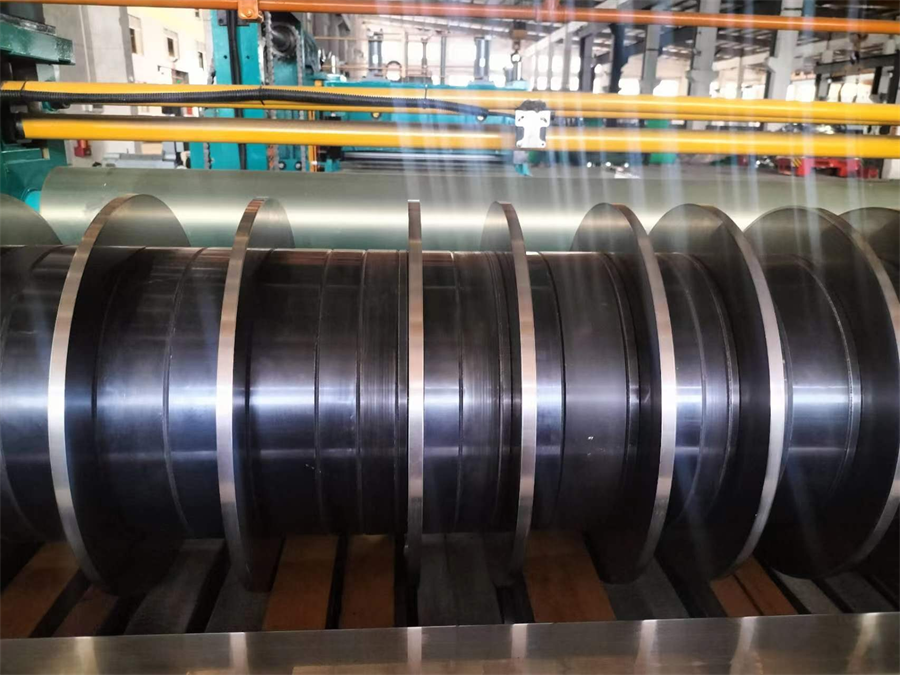

The slit strip material is buffered by a loop and enters the tension station through two sets of separation devices. The required winding tension is established through the tension device and the coiler to prevent collapse after winding. Finally, the unloading mechanism unloads the material roll from the receiving shaft to the discharge trolley and transports it out.

Parameters Of Aluminum and Copper Foil Automatic Slitting Line

| Raw material parameters | ||

| 1 | Roll width | 350-1200mm |

| 2 | Strip thickness | 0.25mm~2.0mm |

| 3 | Roll weight | ≤ 14 ton |

| 4 | Inner diameter of material roll | Φ 508mm |

| 5 | Maximum outer diameter | Φ 1800mm |

| 7 | Material state | Soft state, Semi hard state, Hard state, Extra hard state |

| Discharge parameters | ||

| 1 | Cutting width: | 25-1200mm |

| 2 | Inner diameter of material roll | Φ 508mm |

| 3 | Maximum outer diameter | Φ 1800mm |

| 4 | Finished roll weight | ≤ 14T |

| 5 | Cutting ability | With the 2.0mm thickness, cutting strips can reach 15 |

| Shear quality | ||

| 1 | Burr tolerance | ≤ 3% of plate thickness (semi hard, hard)≤ 5% of plate thickness (soft)

|

| 2 | Width tolerance | ± 0.1mm (width>100mm) ± 0.05mm (width ≤ 100mm) |

| 3 | Length accuracy | ≤± 3 ‰ |

| Unit parameter | ||

| 1 | Shearing speed | 0-150m/min |

| 2 | Power supply | 380V/50Hz/3Ph |

| 3 | Installed capacity | ≈ 220KW |

| 4 | Control method | AC control |

| 5 | Working floor | 24m x 8m |

| 6 | Operator | 1 technical worker, 2 general workers |

Key Features Of Aluminum and Copper Foil Automatic Slitting Line

Customizable Of Aluminum and Copper Foil Automatic Slitting Line

The aluminum slitting line offers the flexibility in terms of customization. Manufacturer can easily adjust the width of the slit strips according to their specific requirements. We also could customized the parameter or configuration as you request, most welcome you contact our through our website or e-mail.

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com