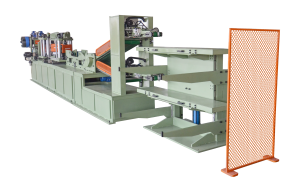

Main Character of spacer punching machine

1.Spacer punching machine adopts numerical control structure and is easy to operate. It only needs to input the length and quantity of spacer through the touch screen to complete the punching process automatically

2.Safety facilities are complete and equipped with safety light curtain to prevent operators from accidental injury

3.Spacer punching machine with operation panel, counting and quantity preset function.

4.The total power of portable system is less than 1.2kW. Power supply AC380V, 50Hz

5. FR4 table, no pollution to cardboard

Main Technical Parameter for insulating material spacer punching machine

| Feeding width | 20~50 |

| Spacer length | 15~1000mm |

| Processing material | Thickness 1.3-3mm |

| Machine width and hardness | 400、Rc52 |

| Feeding accuracy | ±0.2 |

| Max stack thickness of feeding table (mm) | 300 |

| Fluse length | ≈10 |

| Tail length | ≈50 |

| Max feeding speed | 150(/min) |

| Punching ton | ≥40KN |

| Total power | ≤1.2kw |

| Total weight | 700kg |

Main Function for insulating material spacer punching machine

1. The out of waste and finished material should be in the same direction

2. Length of working table ≥ 2500mm

3.FR4 insulation board is used for automatic feeding table

4. The main body of the punch is made of cast steel and 40Cr alloy steel

5. The equipment maintenance is convenient and reliable, easy to check and maintain. The equipment is easy to be lubricated without oil leakage. The overall shape of the equipment is neat and beautiful.

6.The buttons of each operating handle are flexible, without blocking and blocking

7.The electrical components are Schneider, Omron, Chint and other brands, and the pneumatic parts are made of Taiwan Airtac, Japan SMC or Taiwan qilike.

https://youtu.be/6uHIhA9JzEU

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com