Center leg is, center of E part(core) witch is in the middle and winding(primary and secendery coil) around this and thickness is total core stacking. This kind of transformer core cutting machine can be used to cut the iron core sheet with maximum width 300mm and punch holes on the sheet. With different parameters input in a touch screen, the transformer core cutting machine can be used to cut different shapes of the core legs, for instance, the equilateral core limb, eccentric center core limb and so on. With PLC control system and a touch screen, it is very easy to operate the transformer core cutting machine.

Processing range of core cutting machine

| Length of cut | 240~1500mm |

| Core steel width | 30~300mm |

| Core steel thickness | 0.23~0.35mm |

Processing tolerance for cutting machine

| Cutting length tolerance | ≤±0.15mm |

| Angle | ≤±0.025º |

| Burr | ≤0.02mm |

Coil standard of transformer core cutting machine

| Width tolerance | ≤±0.1mm |

| Burr | ≤0.03mm |

| S°tolerance | ≤0.2mm/2m |

Core cutting machine productivity

| Feeding speed | 0~150m/min |

| Shear efficiency | About 45 piece/min (without punching) |

Transformer cutting line type processing

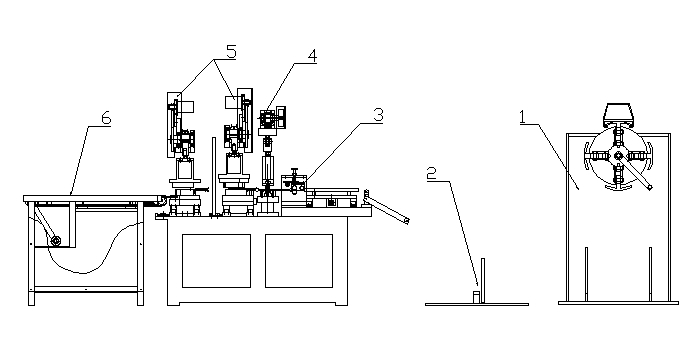

Lamination core cutting machine equipment drawing

FAQ

Yes, we have the rich experience for establish new transformer factory.

And had succeeded in help Pakistan and Bangladesh customer to build transformer factory.

No,most of machines are designed according to customers’ specification ,such as core size/ coil size or any drawing

If you don’t know that, please contact us ,we can provide the guidance .

The quality is approved by national certificate ,several senior inspection personnel ,the brand material supplier ensure the safety and reliability of everything from storage to finished the goods .

It’s optional .Our company will provide the guidance and videos for installation and commissioning.

If you need ,we can send engineers for for overseas installation and training.

The warranty period is 12 months .During Any problems ,our company will respond within 24 hours .

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com