The punching unit has turret tooling library, it maximally can hold 8 (punch and embossing) dies or 7 punch dies and 1emossing die;

The Bend Unit adopts overall structure ,angular CNC method, operation is simple and high accuracy;

The Shear Unit adopts circular overall structure, its design is new and unique ,proper stress ,which can guarantee long time usage without deformation;

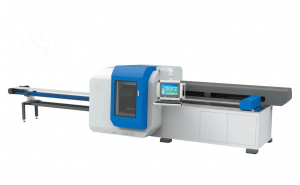

Feature Of Busbar Machine

Busbar Cutting Punching And Bending Machine adopts dual layer platforms design scheme, three units can be operated at the same time without disturbing each other.

Busbar Punching Bending Cutting Machine is equipped with auto refueling and draining system ,the operation is simple and convenient, the hydraulic oil enters oil tank through the filter, which can protect the whole hydraulic system from any contamination;

Busbar Cutting Punching Bending Machine adopts stainless steel oil tank, which can guarantee no corrosive degeneration of the hydraulic oil and extend the usage life span of hydraulic oil and each sealing parts;

PLC control, stable and reliable.

Technical Data For Busbar Punch Cut Bend

| Item | Materials | Processing Thickness×Width | Max punch | Max output power |

| Punch unit | Copper /Aluminum | Thickness:15mm | 25 | 350KN |

| Shear unit | 15×160mm | |||

| Bend unit | 15×160mm |

Configuration Of Busbar Processing Machine

| Dimension of platform (mm) | Weightof the machine(kg) | Numberof motor | Total power of motors (kw) | Work of voltage (v) | Number of hydraulic station and specification (Mpa) | Control method |

| Layer 1:1500×1200 | 1460 | 4 | 11.37 | 380 | 3×31.5 | PLC + bending angle mumerical control |

| Layer 2:840×370 |

FAQ

We have the standard model recommend to you, or you could give us your processing thickness and width, we could customize it for you.

Yes, we have rich experience for establish a new transformer factory. And had successfully helped Pakistan and Bangladesh customers to build a transformer factory.

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com