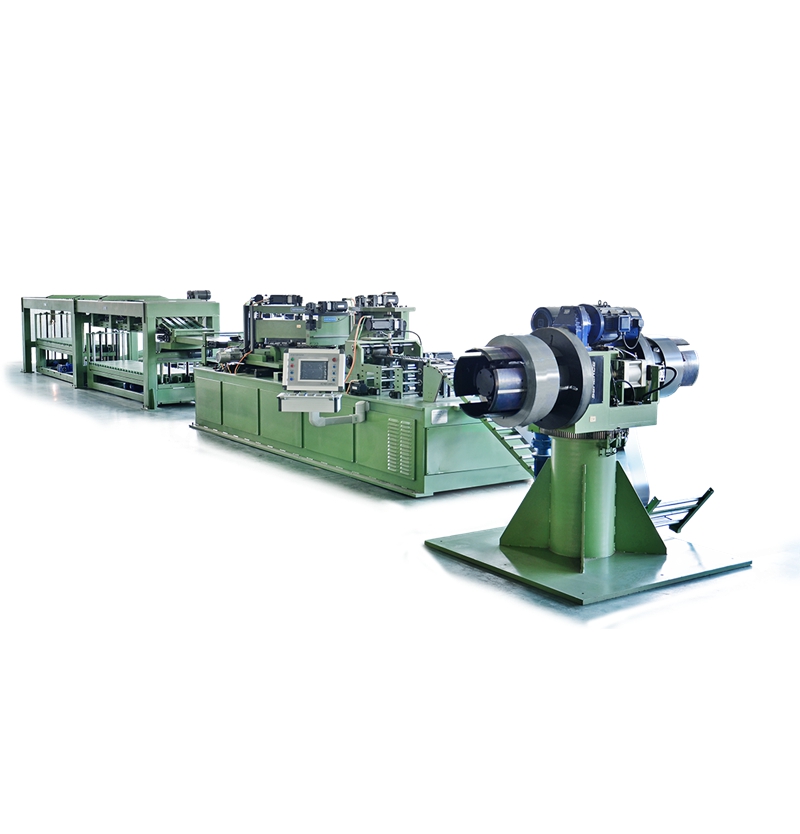

The transformer shear production line adopts multiple sets of AC servo system. Respectively used in: material transmission channel by servo motor to set material width in screen operation and automatic positioning. Shearing and v-notching adopt AC servo motor as driving power, with fast response speed, low noise, small vibration, convenience maintenance.

Features

Frequency speed decoiler, automatic tracking system.

Electrical control double loading , Easy position Replacement.

No need pit for Material Storage Device, Ensure safe and convenient.

PLC Control, Servo adjust width, Servo feed

V notching, Hole punching, Shearing device kinds of collocation, meet all kinds of needs

Automatic depiler, stacking neatly

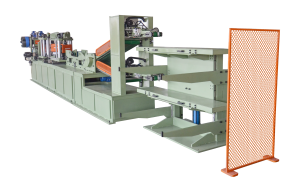

Core type by transformer core lamination machine

Two shear one punch

Two shear two punch

Two-shear Two-punch Central Positioning Stepping

Technical parameter

|

Transformer Core Cutting Machine |

||||

|

Equipment model |

HJ-300 |

HJ-400 |

HJ-600 |

|

|

Processing range |

Sheet Length (mm) |

400--1800 |

400--2200 |

400--3500 |

|

Sheet Width (mm) |

40--300 |

50--400 |

60--600 |

|

|

Thickness of sheet(mm) |

0.23--0.35 |

|||

|

Process precision |

Tolerance of length(mm) |

≤±0.15 |

||

|

Shearing angle |

±0.025º |

|||

|

Shearing burr(mm) |

≤0.02 |

|||

|

Coil specification |

Tolerance of width(mm) |

≤±0.1 |

||

|

Burr(mm) |

≤0.03 |

|||

|

Tolerance of S(mm/2m) |

≤0.2 |

|||

|

Feeding speed(m/min) |

0--180 |

0--200 |

0--200 |

|

|

Shear efficiency |

Width 160mm,With a v-notch yoke L1 length 800 mm ,Side leg L1 length 600 mm ,Shear combination, more than or equal 36 times per minute |

Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 30 times per minute . |

Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 36 times per minute. |

|

|

De-coiler |

Quantity |

Double head |

||

|

Max.loading /single head (kg) |

1500 |

1800 |

2000 |

|

|

Coil innner dia mm |

Φ500 |

|||

|

Max coil outer dia mm |

Φ1000 |

|||

|

Docoiler speed m/min |

0--180 adjustable |

|||

|

Expanding range mm |

Φ480--Φ520 |

Φ480--Φ520 |

Φ480--Φ520 |

|

|

Buffer device |

no pit |

|||

|

Feeding form |

Single servo feeding |

Single servo feeding |

Double servo feeding |

|

|

V-notching |

Notching arrange(mm) |

±25 |

±25 |

±35 |

|

Steplap |

7 steps |

|||

|

Punching device |

without |

1 unit |

1 unit |

|

|

Shearing device |

2 unit(45º&135º each have one unit ) |

|||

|

Depiler |

Devide material up and down, stacking |

|||

|

Total Powerkw |

25 |

30 |

45 |

|

|

Power supply |

380V±10% 50Hz (Or Customized) |

|||

What is Trihope?

5A Class Transformer Home with a full solution for the Transformer Industry

1, A real manufacturer with complete in-house facilities

2, A professional R&D Center, having collaboration with well-know Shandong University

3, A top performance company certificated with International Standards like ISO, CE, SGS and BV etc

4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc.

5, A reliable business partner, served for ABB, TBEA, PEL, ALFANAR, ZETRAK etc

Q3: How to grantee the quality ?

The quality is approved by national certificate ,several senior inspection personnel ,the brand material supplier ensure the safety and reliability of everything from storage to finished the goods .

Q4:Do you provide overseas installation and training ?

A: It’s optional .Our company will provide the guidance and videos for installation and commissioning.

If you need ,we can send engineers for for overseas installation and training.

Q5:How long is the warranty ?

A:The warranty period is 12 months .During Any problems ,our company will respond within 24 hours .

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com

-300x109.jpg)