The walls and covers of the tank are made of corrugated steel. The corrugation provides additional strength to the tank and makes it more resistant to damage during transportation and assembly. The corrugated tank design also provides better heat dissipation, reduces noise, and improves insulation.

Working flow of the transformer oil tank fin forming line

Uncoiling -- coil feeding -- plate folding -- cutting -- run-out

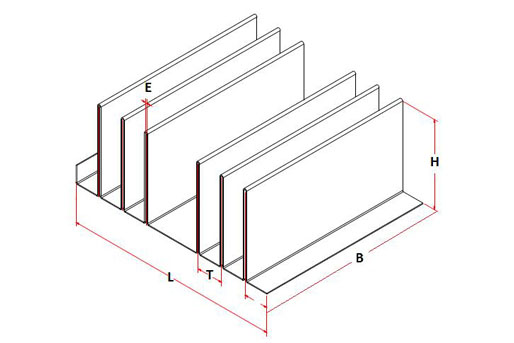

Technical Parameter For Corrugated Fin Wall Panel Forming Machine

|

Item |

Code |

Parameter |

Parameter |

|

Steel plate width |

B |

300-1300mm |

300-1600mm |

|

Steel plate thickness |

S |

1-1.5mm |

1-1.5mm |

|

Corrugated height |

H |

50-350mm |

50-400mm |

|

Corrugation pitch |

t |

≥45mm |

≥40mm |

|

Net clearance between corrugations |

e |

6mm |

6mm |

|

Number of corrugation band sets |

n |

1-4sets |

1-4sets |

|

Corrugation band length |

L |

≤2000mm |

≤2000mm |

|

Folding height |

C |

15-300mm |

15-300mm |

|

Length of box board tips (front gap) |

b |

≥60mm |

≥40mm |

|

Length of box board tips (rear gap) |

a |

≥40mm |

≥40mm |

|

Forming speed |

|

≤40S |

≤40S |

|

Total power of motors |

|

23.65kw |

35kw |

|

Total weight |

|

17000kg |

25500kg |

|

Floor space |

|

9000×6000(mm) |

13000×7100(mm)

|

Features Of Transformer Corrugated Tank Fin Production Line

FAQ

The transformer tank line is a very standard model. The model is depend on the tank max width. We have the model BW-1300 and BW-1600 which can meet the needs of most industries

Yes, we have rich experience for establish a new transformer factory. And had successfully helped Pakistan and Bangladesh customers to build a transformer factory.

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com