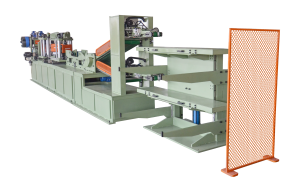

The transformer shear production line adopts multiple sets of AC servo system. Respectively used in: material transmission channel by servo motor to set material width in screen operation and automatic positioning. Shearing and v-notching adopt AC servo motor as driving power, with fast response speed, low noise, small vibration, convenience maintenance.

Features

Frequency speed decoiler, automatic tracking system.

Electrical control double loading , Easy position Replacement.

No need pit for Material Storage Device, Ensure safe and convenient.

PLC Control, Servo adjust width, Servo feed

V notching, Hole punching, Shearing device kinds of collocation, meet all kinds of needs

Automatic depiler , stacking neatly

Core type by transformer core lamination machine

Two shear one punch

Two shear two punch

Two-shear Two-punch Central Positioning Stepping

Technical parameter

|

Transformer Core Cutting Machine |

||||

|

Equipment model |

HJ-300 |

HJ-400 |

HJ-600 |

|

|

Processing range |

Sheet Length (mm) |

400--1800 |

400--2200 |

400--3500 |

|

Sheet Width (mm) |

40--300 |

50--400 |

60--600 |

|

|

Thickness of sheet(mm) |

0.23--0.35 |

|||

|

Process precision |

Tolerance of length(mm) |

≤±0.15 |

||

|

Shearing angle |

±0.025º |

|||

|

Shearing burr(mm) |

≤0.02 |

|||

|

Coil specification |

Tolerance of width(mm) |

≤±0.1 |

||

|

Burr(mm) |

≤0.03 |

|||

|

Tolerance of S(mm/2m) |

≤0.2 |

|||

|

Feeding speed(m/min) |

0--180 |

0--200 |

0--200 |

|

|

Shear efficiency |

Width 160mm,With a v-notch yoke L1 length 800 mm ,Side leg L1 length 600 mm ,Shear combination, more than or equal 36 times per minute |

Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 30 times per minute . |

Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 36 times per minute. |

|

|

De-coiler |

Quantity |

Double head |

||

|

Max.loading /single head (kg) |

1500 |

1800 |

2000 |

|

|

Coil innner dia mm |

Φ500 |

|||

|

Max coil outer dia mm |

Φ1000 |

|||

|

Docoiler speed m/min |

0--180 adjustable |

|||

|

Expanding range mm |

Φ480--Φ520 |

Φ480--Φ520 |

Φ480--Φ520 |

|

|

Buffer device |

no pit |

|||

|

Feeding form |

Single servo feeding |

Single servo feeding |

Double servo feeding |

|

|

V-notching |

Notching arrange(mm) |

±25 |

±25 |

±35 |

|

Steplap |

7 steps |

|||

|

Punching device |

without |

1 unit |

1 unit |

|

|

Shearing device |

2 unit(45º&135º each have one unit ) |

|||

|

Depiler |

Devide material up and down, stacking |

|||

|

Total Powerkw |

25 |

30 |

45 |

|

|

Power supply |

380V±10% 50Hz (Or Customized) |

|||

What is Trihope?

5A Class Transformer Home with a full solution for the Transformer Industry

1, A real manufacturer with complete in-house facilities

2, A professional R&D Center, having collaboration with well-know Shandong University

3, A top performance company certificated with International Standards like ISO, CE, SGS and BV etc

4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc.

5, A reliable business partner, served for ABB, TBEA, PEL, ALFANAR, ZETRAK etc

Q3: How to grantee the quality ?

The quality is approved by national certificate ,several senior inspection personnel ,the brand material supplier ensure the safety and reliability of everything from storage to finished the goods .

Q4:Do you provide overseas installation and training ?

A: It’s optional .Our company will provide the guidance and videos for installation and commissioning.

If you need ,we can send engineers for for overseas installation and training.

Q5:How long is the warranty ?

A:The warranty period is 12 months .During Any problems ,our company will respond within 24 hours .

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com

-300x109.jpg)