The milling composite machining integrated machine is an advanced machining equipment that integrates turning, engraving, and carving functions. It can complete turning and milling composite machining in one clamping, thereby improving machining efficiency and accuracy. This equipment adopts CNC technology to achieve complex pattern carving function, which can realize multi process composite processing of cylindrical, conical, curved and other wooden products. It has the characteristics of stable processing accuracy and high finished product qualification rate, greatly improving the production efficiency of the insulation workshop.

Operating environmental conditions of Integrated sawing and milling machine is that altitude is less than 2000m; and ambient temperature is maintain normal operation at -20℃ ~ 50℃;Earthquake intensity is no more than 6 degrees.

Technical parameter for insulation board processing machine

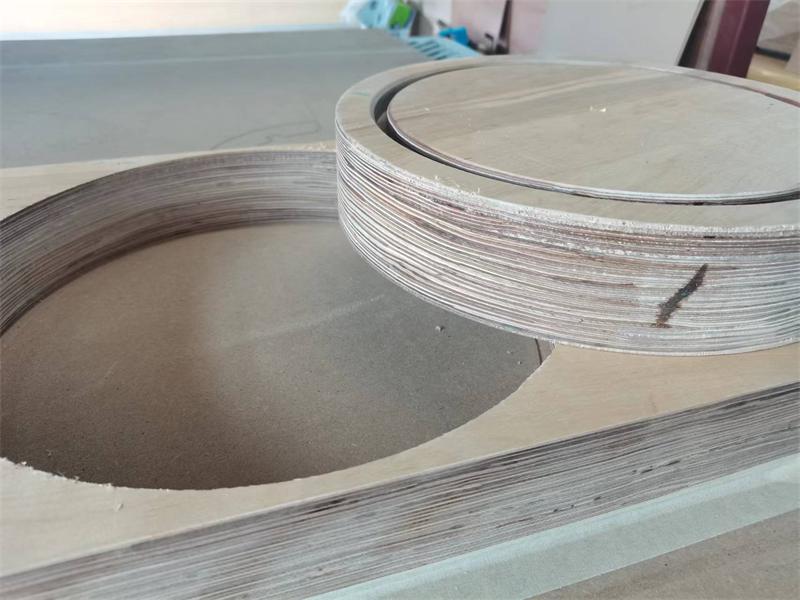

● Insulation board processing machine is equipped with milling, X-axis and Y-axis sawing functions, and each function can operate independently without interference.

● Integrated sawing and milling machine is with wireless control handle.

● Insulation material milling machine shall be equipped with four lifting rings for easy lifting.

● Main technical performance of sawing and milling machine.

● The whole structure of insulation material sawing and milling machine meets the requirements of stiffness, has good stability and will not produce shaking phenomenon.

●The control cabinet for insulation material sawing and milling machine is equipped with emergency stop button and dust collector start button.

●The X, Y and Z axes are equipped with hardware travel limit and limit switch.

Effective stroke of saw milling: 3000mm×150mm×260mm. The milling function requires that the workpiece with a thickness of 100mm can be milling, and there is no interference with the saw blade during milling.

Repeated positioning accuracy: ±0.2mm. It is required that the workpiece surface of the saw blade shall not have flutter scratches and other defects, and the workpiece shall not be carbonized, lug or ellipse.

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com