Bus bars are an important component in the manufacture of transformers. They are a solid element that allows a flexible way of transmitting and distributing power. Busbars are produced in a variety of shapes, including flat strips, solid bars and rods, and are typically composed of copper, brass or aluminium as solid or hollow tubes.Some of these shapes allow heat to dissipate more efficiently due to their high surface area to cross-sectional area ratio.

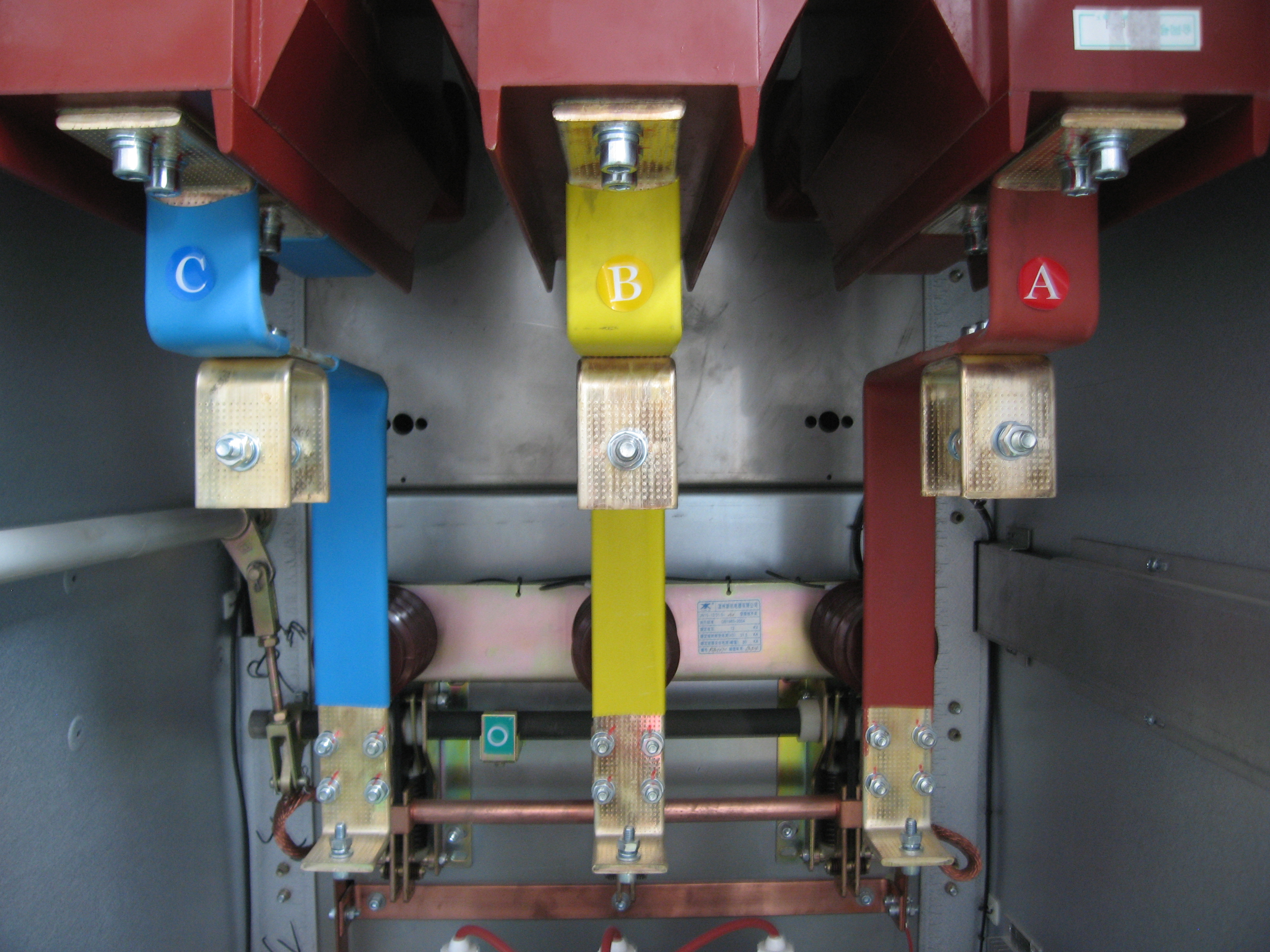

In electric power distribution, a busbar (also bus bar) is a metallic strip or bar, typically housed inside switchgear, panel boards, and busway enclosures for local high current power distribution. They are also used to connect high voltage equipment at electrical switchyards, and low voltage equipment in battery banks. They are generally uninsulated, and have sufficient stiffness to be supported in air by insulated pillars. These features allow sufficient cooling of the conductors, and the ability to tap in at various points without creating a new joint.

Our company Multi-functional Busbar Process equipment has three units:Punching ,shearing and bending . We can supply multifunctional equipment or seperate function equipment as you choose. https://www.youtube.com/watch?v=IjDFvbM0ae8

The punching unit has turret tooling library, it maximally can hold 8 (punch and embossing) dies or 7 punch dies and 1emossing die;

The Bend Unit adopts overall structure ,angular CNC method, operation is simple and high accuracy;

The Shear Unit adopts circular overall structure, its design is new and unique ,proper stress ,which can guarantee long time usage without deformation;

Post time: Apr-12-2023

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com