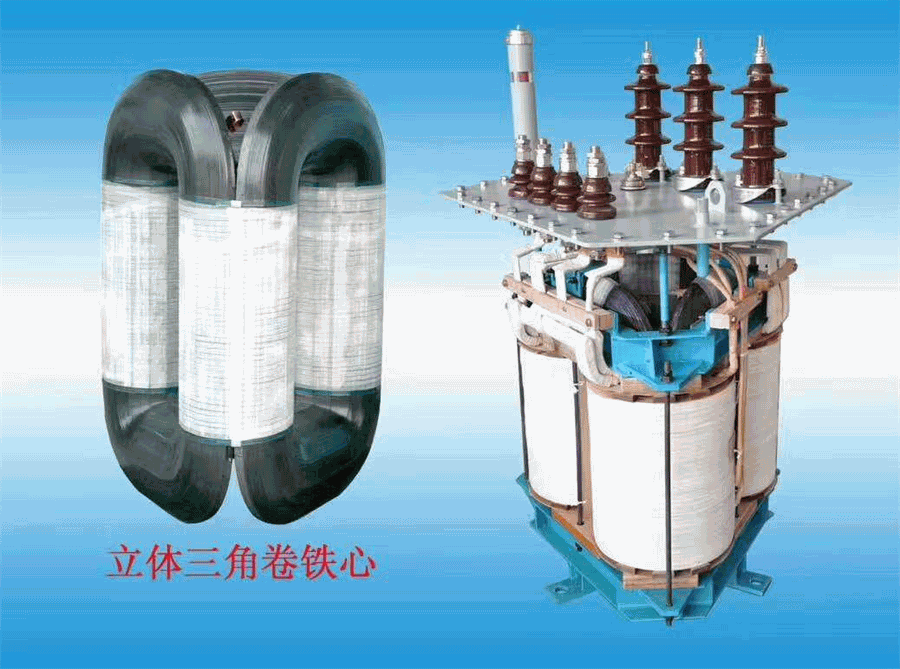

A series of problems, such as larger diameter, the formation of waves on the cylinder, the deviation of the verticality of the assembly, and the unqualified performance after annealing during processing, are common problems in the stereoscopic wound core industry, especially for new companies. The processing quality directly affects the product quality of the stereoscopic wound core transformer, especially the consistency of the product. Theses are all practical problems must be faced to control the quality to reduce the scrap rate and improve the competitiveness of the product in the industry.

A series of problems, such as larger diameter, the formation of waves on the cylinder, the deviation of the verticality of the assembly, and the unqualified performance after annealing during processing, are common problems in the stereoscopic wound core industry, especially for new companies. The processing quality directly affects the product quality of the stereoscopic wound core transformer, especially the consistency of the product. Theses are all practical problems must be faced to control the quality to reduce the scrap rate and improve the competitiveness of the product in the industry.

Larger Diameter

The actual thickness of the silicon steel sheet is different from the standard of the design ed drawing. The product quality of each silicon steel manufacturer has a certain unevenness, even if it is a qualified product under national standards. The difference between the same sheets of each roll is also different. What’s important is to see who has the smallest difference of the same sheet., which requires transformers or iron core manufacturers to use each CRGO in the process to identify them based on their own experience whether the quality of the material meets their quality requirements.

The national standard for CRGO requires the thickness of silicon steel strip to be measured at any place not less than 15mm away from the edge of the steel strip with a 0.01mm precision micrometer, and the size of CRGO with a thickness of 0.23mm, 0.27mm, 0.30mm with a width of <150mm or >150-400mm Allow deviation.

The allowable deviation of thickness, longitudinal thickness difference, lateral thickness difference and width allowable deviation of CRGO strip shall meet the requirements of the following table.

| Nominal Thickness | Allowable Deviation of Thickness | Lateral Thickness Difference | Longitudinal Thickness Difference | Allowable Deviation of Width | |

| Edge Cuttted | Edge no Cutted | ||||

| 0.23 | ±0.025 | ≤0.030 | ≤0.020 | 0~+2 | 0~+5 |

| 0.27 | ±0.030 | ||||

| 0.30 | |||||

| 0.35 | |||||

Unit:mm

The unevenness (waviness) of the CRGO strip should not be greater than 1.5%. At any measurement length of 2m, the sickle bend of the CRGO strip should not be greater than 1.0mm. The size and shape should be measured at a position not less than 3m away from both ends of CRGO strip.

The burrs produced during the processing of the silicon steel sheet have a certain impact on the super-large diameter of the stereoscopic wound core. The presence of the burrs will inevitably affect the quality of the core. Assembling to the transformer will cause the eddy current of the transformer to increase, which will generate a lot of heat, and will affect the quality and life of the transformer. Can the iron core burn off the burrs during the annealing process? 0.23-0.35 CRGO processing burrs are allowed to be controlled within ≤0.02mm. The production of burrs must be strictly controlled during the slitting and curve cutting process. Of course, it is not realistic to have no burrs, so frequent inspections and frequent grinding of the tools are required. Keep burrs to a minimum, because soft burrs can be burned off during annealing, but hard burrs cannot be burned off.

Conclusion: The difference in core diameter is directly related to the thickness of the material.

Solution: Select a silicon steel strip with uniform material thickness and small sheet difference to effectively control processing burrs (select tools suitable for material hardness and toughness)

The core cylinder forms waves

The stereoscopic wound cores may have cylindrical waves during processing. Two cases should be distinguished here. The first case is the waves formed before annealing. This may be due to material factors and equipment factors. The flatness of the material and the thickness tolerance mentioned above will also occur. There is also a curling phenomenon in the material itself, especially It is the side material of the large roll. Excessive rewinding force during slitting or curved opening causes deformation of the coil. Insufficient tension of the winding core causes the inner frame to be too loose to form waves.

The second case is the wave formed after annealing. The possible factor here is that the die core block is deformed at high temperature, which causes the core to loosen and form a wave. There is also the voids formed after the soft burrs are burned during the annealing process mentioned above, and some of the hard burrs still exist, causing the cylindrical surface to form waves. In the annealing process, the rate of heating and cooling is controlled. The temperature of the furnace is too high, and the ambient temperature and humidity during the furnace have a certain effect on the iron core.

Conclusion: The formation of waves on the iron core cylinder is directly related to the material, the inner frame is too loose, to the processing technology, processing treatment, and to the rate of heating and cooling during the annealing process.

Solution: Choose good-quality CRGO, strictly control the influence of human factors on the quality of the wound core during processing, and choose high-temperature mold core blocks.

TRIHOPE is backed by more than hundred suppliers to supply components and materials used in transformers, including CRGO, densified wood, insulation paper. We have a professional technical team with many years of experience in Transformer field, not only providing you high quality products, also solving all kinds of technical problems and valued services.

Furthermore, We have strong capability to provide Turn-Key Service for new establishment of transformer factory and CT&PT factory. Your satisfaction will be our greatest motivation.

Post time: Mar-22-2021

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com