The commonly used transformer core cutting equipment includes the slitting line and the core cutting line

The slitting line is mainly used for the split of silicon steel sheet in transformer, motor and other industries. The disc blade is used to slit the silicon steel sheet with a certain width into several pieces of material with the width we need. At present, our production of slitting machine includes the following device: Loading trolley, Feeding car, Loop pit guiding device , Stationary guiding device, Main slitting equipmentTension device, Hydraulic winding device , Unloading trolley, Hydraulic station , Electrical control system

The main features of the equipment are high shear precision, small burr, fast speed, automatic control, especially suitable for the performance sensitive silicon steel strip shear.

Automatic core cutting line is a special equipment used for core shear of transformer iron chips. It has the functions of shearing, punching and V-punching. It is used for cutting various kinds of transformer core piece shape. The shear line produced by our company can realize the shear of stepping iron chip, and has the function of on-line fault diagnosis. The equipment is composed of double head de-coiler device, storage device, feeding device, v-notching, hole punching device, shear device, transmission device, depiler device, stacking device and electric control system.

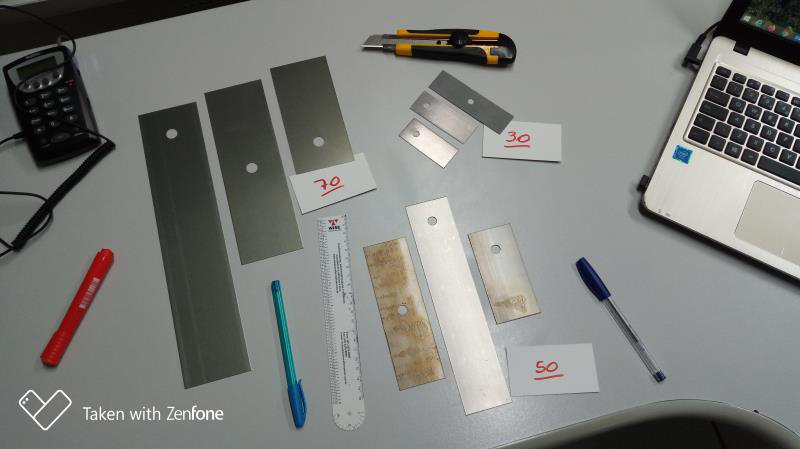

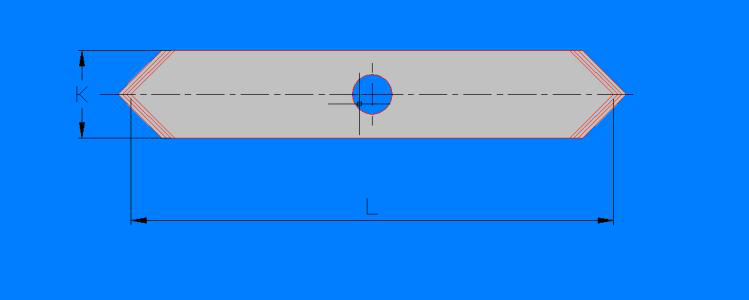

In order to meet the needs of some customers for single sheet shape, we also have economical single equipment, such as 90 degree core shearing machine (as shown in the picture below), Center Leg cutting machine (as shown in the picture below). This type of equipment as a supplement to the full automatic core cutting line can effectively provide production efficiency.

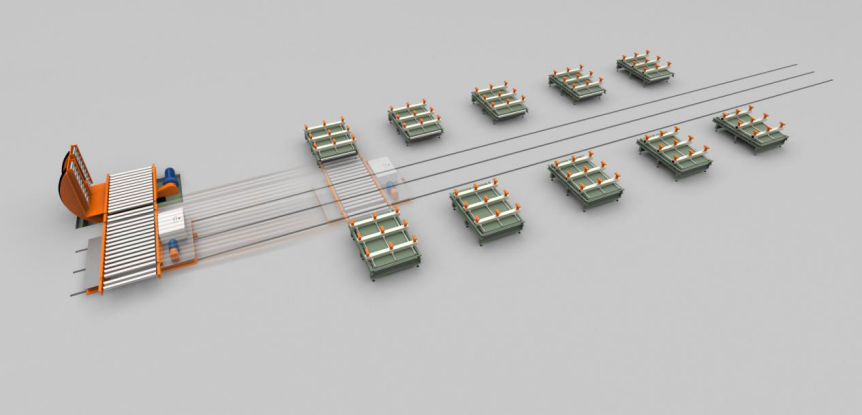

The core stacking is a very important process before the core forming, and at present the core sheet type increases accordingly, so the automatic folding, turnover equipment is more and more popular in the market. Our company core stacking line is consist of Raceway type worktable, Mobile stack platform, Electric transport trolley, Core turning table,Output raceway ,Storage roller. The assembly line mode is adopted to make the traditional iron core lamination process layout more compact, at the same time, the demand for driving is cancelled ,the working efficiency is improved.(as Show in below picture)

Post time: Oct-30-2020

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com