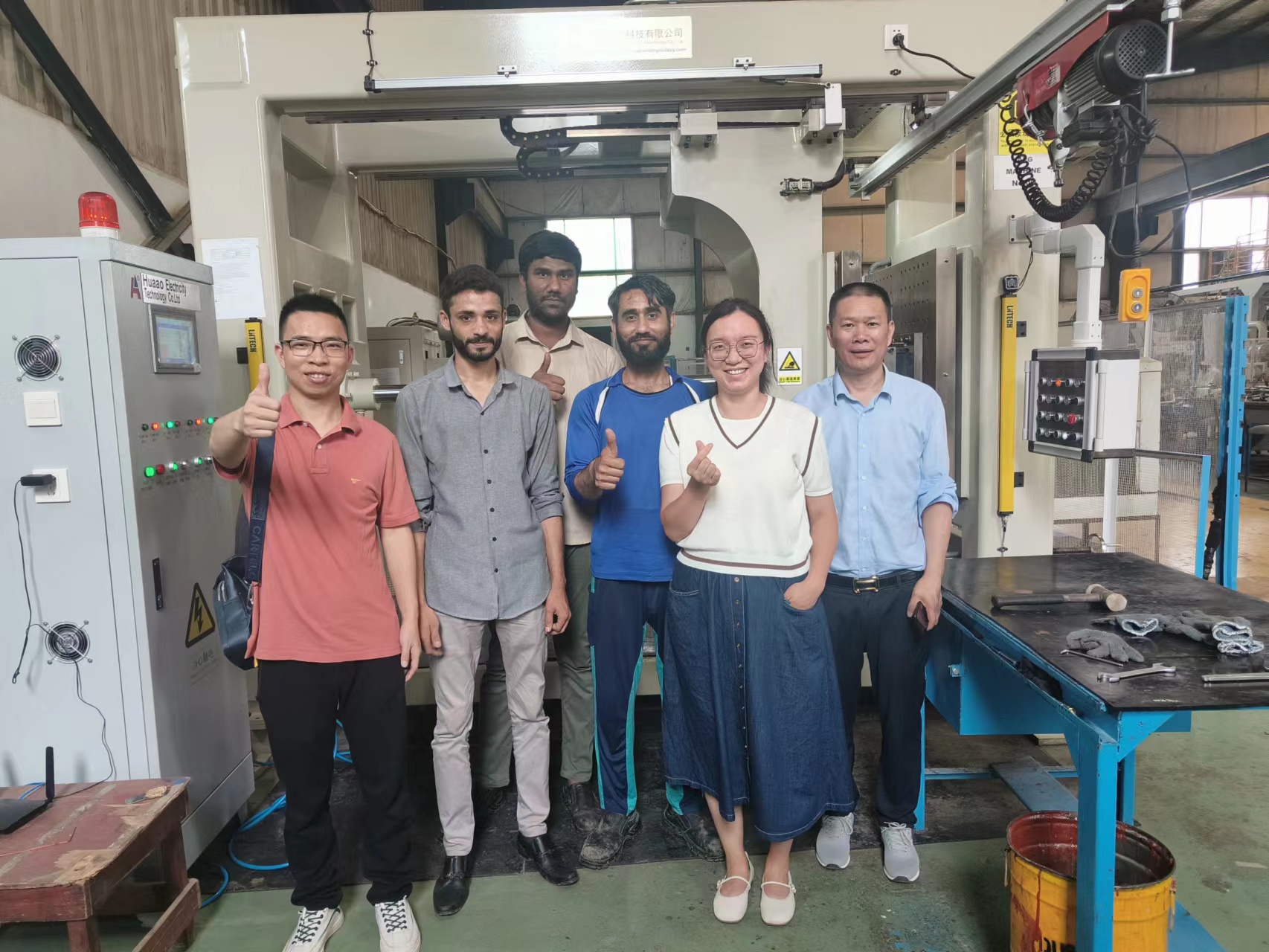

The First APG unit for CT PT installed in Pakistan Biggest Transformer Factory

Epoxy resin CT PT APG injection machine– the most common reactive molding process used for high-volume production – can be characterized by short molding cycles (minutes) and high accuracy.

Epoxy Molding press machines are used to mold or encapsulate electrical and electronic components such as insulators, coils, resistors CT’s, PT’s. Carbon fibre epoxies a composite material are used in aerospace industry for various structural and hardware parts in the aircraft for light weight and high strength properties.

The mould clamping machine has been especially developed for processing Epoxy casting resin systems by the pressure gelation technique. Construction of these Machines are with Horizontal and Vertical Clamping devices, with Heating and Molding – plates as well as integrated Ejecting and Degassing by Tilt mechanisms. The machines are equipped with electronic controls. Our company design can do 2 cavities/ 3 cavities CT , and 6 cavities insulator/bushing

The main process include Hardness, filler raw material pre-mix → Install 2 cavities CT/PT molds → install CT/PT activities parts → Inject resin. De-mold → Get Current transformer/ Potential transformer.

The Whole processing you could check on our link:

https://www.youtube.com/watch?v=2HkHCTPBR9A

Trihope are capable to provide Turn-Key Service for new establishment of transformer factory and CT&PT factory. Any inquiry, please contact us freely .trihope@aliyun.com

Post time: Jul-03-2023

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com