These series of medical molecular sieve oxygen generator equipment based on zeolite molecular sieve adsorbent, using PSA (Pressure Swing Adsorption PSA) for making medical oxygen equipment (hereinafter referred to as oxygen generator), in the process of oxygen generation of raw materials and finished product oxygen air filtration purification layer by layer, to ensure that the output of finished product oxygen to fulfill the requirements of medical technical indicators.

These series of medical molecular sieve oxygen generator equipment is under the normal temperature low pressure air as raw material, the oxygen in the air (about 21%) directly using the method of physical separation, to produce high purity medical oxygen, producing oxygen concentration of 93%-95%, its characteristic is to produce oxygen is fast, safe, economic, convenient, easy to replace the old bottled oxygen and liquid oxygen, in recent years, various types of medical institutions in China are widely promotion and application.

Parameters Of Transformer Coil High Voltage Layer Coil Winding Machine

| Item | Parameters |

| Center height | 1200mm or customized, can up to 1600 |

| Center distance of spindle | 1350mm or customized |

| Working torque | Max 6000 N/M |

| Rotation speed | 0-30 r/min |

| Mode of speed control | Stepless Frequency control |

| Winding parameters | Outer diameter (O.D.) ≤ 1300 mm Rectangular coil diagonal length: ≤ 1300 mm Coil Height: ≤ 1200 mm Winding weight: ≤ 1000 kg |

| Total Power | Around 14 KW |

| Flat wire Pay-off Stand (four heads) | Wire reel inner diameter (I.D.):40mm Wire reel outer diameter (O.D.):600mm Wire reel width: ≤ 300 mm Braking method: pneumatic Power by Servo Motor |

| Layer insulation (Three heads) | Roller inner diameter (I.D.): 76mm Roller outer diameter (O.D.): 400mm Braking method: pneumatic |

| Conductor specification | Flat wire: Max 6x12mm Maximum number of parallel wound wires: 4 |

| Automatic wire ranking function | Can set minimum wire pitch of 0.01 mm |

| Counting mode | 5-digital display, can set total turns and set turns in 20 times, reverse counting available, no loosing data in the event of power-off. |

| Power supply | 3-phae AC 380 V/50 HZ or as per user's need |

| Machine color | Grey RAL7035 or as per user's need |

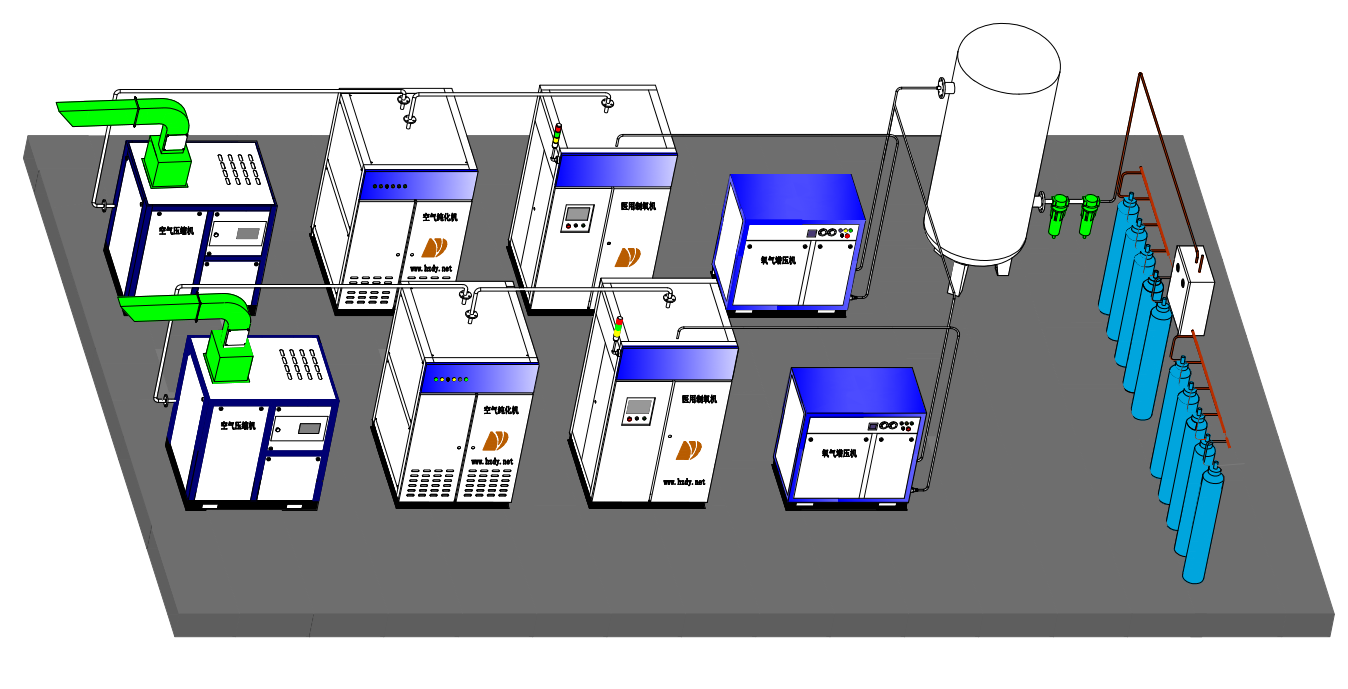

Composition Of Equipment

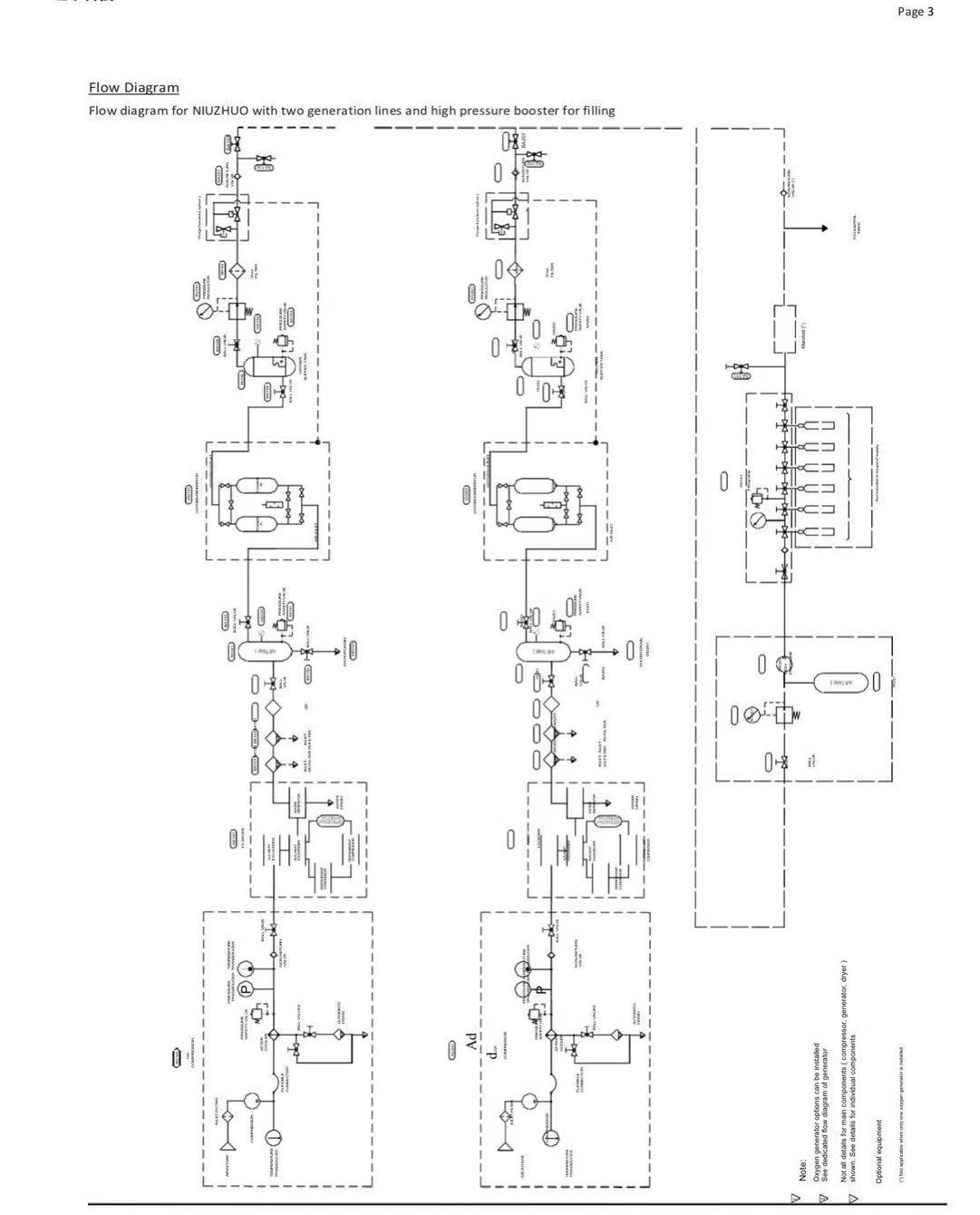

The medical molecular sieve oxygen generator designed by OR Company is mainly composed as follows:

Technical Features Of Oxygen Production Equipment

Technical Features Of Oxygen Production Equipment

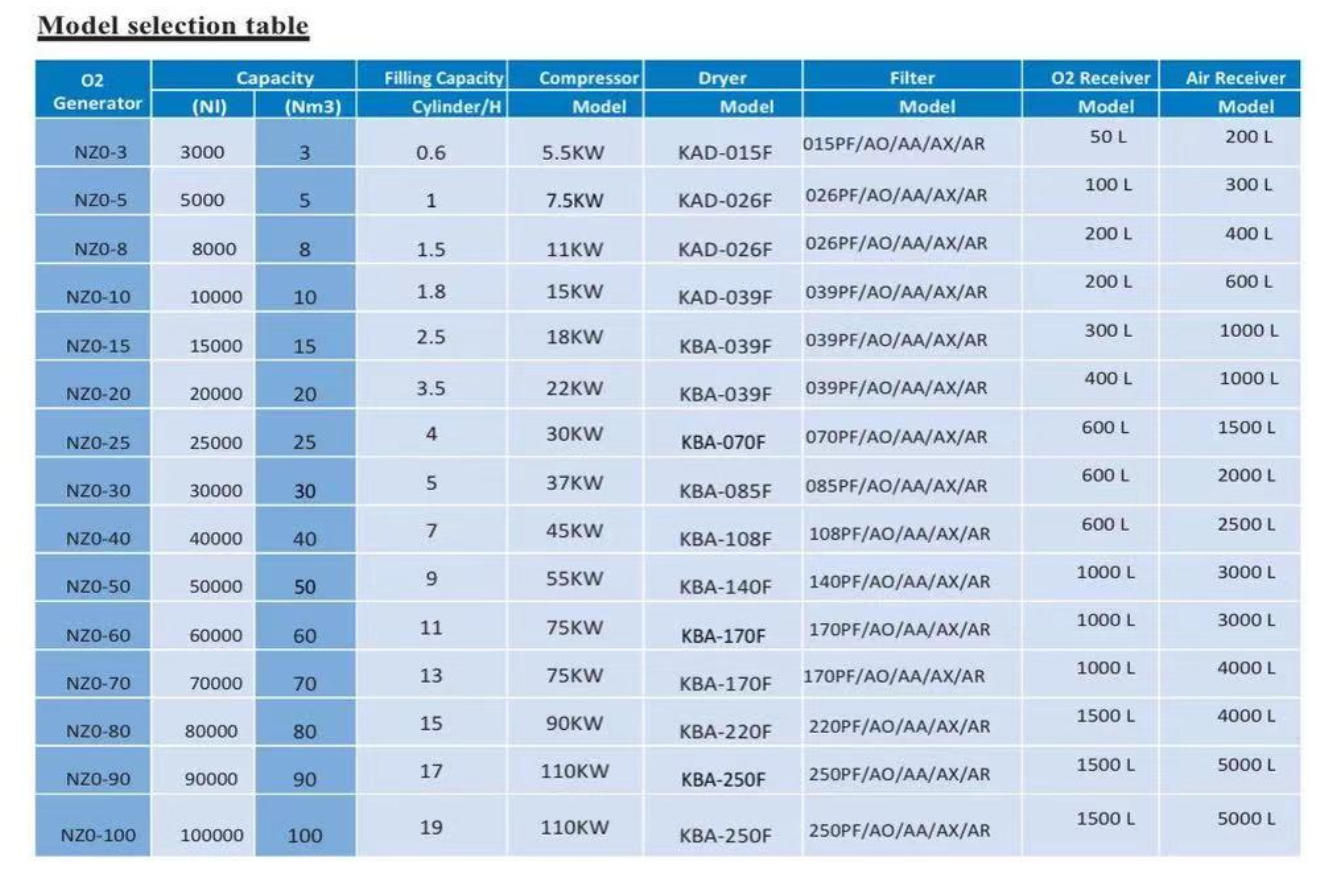

| NO | NZO—15 |

| Oxygen flow | 15Nm3/h |

| Oxygen purity | 93%-95%(VOL)adjustable |

| Oxygen Gas dew point | ≤-40℃ |

| Outlet pressure | 0.3-1.0Mpa (adjustable) |

| Specific air consumption | >6.25Nm3/min/7-8KG |

| Description of design | The pressure of oxygen outlet of psa oxygen generator is 0.3mpa, and the pressure required by oxygen supercharger shall be configured |

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com