high-pressure waterjet cutting technology can cut a wide range of materials using pure water or water mixed with abrasive for very hard materials. The precision and power of the jet enable high-precision cutting, even of complex shapes.Our water jet cutting machine is mainly composed of a CNC cutting platform, ultra-high pressure pump, sand-adding cutting system, automatic abrasive supply system,cooling system, online automatic desanding system, and wastewater sedimentation

and filtration device, among others.

Compared with traditional thermal cutting, water jet cutting has the following advantages:

- No material restrictions, capable of cutting almost any soft or hard material.

- Cold cutting, no heat is generated during the cutting process, eliminating thermal deformation and heat-affected zones.

- High efficiency and good surface quality.

- Can cut any complex shape without the need for molds or special fixtures.

- Small cutting gap, saving materials.

- Environmentally friendly, no toxic smoke or dust, and does not cause new industrial pollution

More technical Details About SmartJet120C Waterjet Cutting Table

|

Item |

Name |

Description |

Details |

|

|

1 |

Structure | /Cantilever Type/Separate Working Tale/Three-side way, easy to load and unload material/Broader applicability: can cut bigger size sheet than cutting size/Stroke of X-axis:3000mm/Stroke of Y-axis: 1200mm

/Stroke of Z-axis: 200mm |

|

|

|

2 |

BASE and Beam | /Heat treatment Welding Base/High Rigid Cross Beam/New Balance Design/Built-in Balance Weight | ||

|

3 |

Outgoing Direction of the Control Cable | /The installation direction of the control cable is optional(Left or Right)/Make sure the cabinet on the same side when two machine face to face installed for space-saving | |

|

|

4 |

Integrated Slider | /Casting Slider/Integrated design to reduce the accumulate error | |

|

|

5 |

Protective Cover | /Stainless protective cover(Base)/Galvanized sheet steel collection tank on the bottom of the casting body/Steel cover for beam | |

|

| Galvanized Sell colletion | Stainless Protetive Cover | |||

|

6 |

X-YTransmission System | /PMI High Precision Linear Guide/PMI High Precision Ball Screw | ||

|

7 |

Working table | /Separated Working Table/Strip support/Support beam height>300mm,sturdy and durable/Hight of the table:850mm,easy to load and unload | ||

|

8 |

Z-axis System | /Aluminum profile structure/PMI linear guide(TBI)/PMI Ball Screw(TBI)/Enclosed protective design | ||

|

9 |

Lubricating System | /Automatically Lubricate/Level indicating/Oil circuit distribute |

|

10 |

Independent mobile operating cabinet | /Independent mobile operating cabinet/i-Telli PC control/English Version/ WEIHONG Control System/USB Interface | |

|

| |

||||

|

11 |

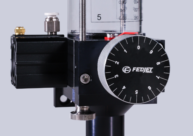

Handwheel | /Wireless Hand Wheel(For WH) | ||

|

12 |

Electrical System | |||

|

13 |

UHP ON/OFF VALVE | /Pneumatic Valve | |

About Trihope

We are a 5A Class turnkey solution provider for Transformer Industry.

The First A: we are a real manufacturer with complete in-house facilities

The second A, we have a professional R&D Center, having collaboration with well-know Shandong University

The Third A, We have Top Performance Certificated with International Standards likes ISO, CE, SGS, BV

The Forth A, We are better cost-efficient supplier equipped with international brand components like Siemens Schneider, etc. And we provide 24 hours 24-hour after-sales service, providing services in Chinese, English, and Spanish

The Fifth A, We are a reliable business partner, served for ABB, TBEA, ALFANAR, PEL, IUSA etc in the last decades, And our customer are more than 50 countries all over the world.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com